1947 Helms Bakery DIVCO

1947 DIVCO – VIN UM39575

THIS VEHICLE IS NOW BEING PAINTED HELMS COLORS

In the late 1920s, the temperate climate of Southern California drew many people to migrate from chillier places, and that included Paul Helms, a New Yorker who came out in 1926 to improve his health. He opened up a bakery at the corner of Venice and Washington on March 2, 1931, and had in his employ 32 people…and 11 trucks, Helms called coaches. The building, and Paul Helms’ desk itself, actually straddles Culver City and Los Angeles! This building still exists today at 3225 Helms Ave., Culver City, California. Since the horse & wagon days Home delivery was becoming a big part of American life and the Helms bakery grew rapidly.

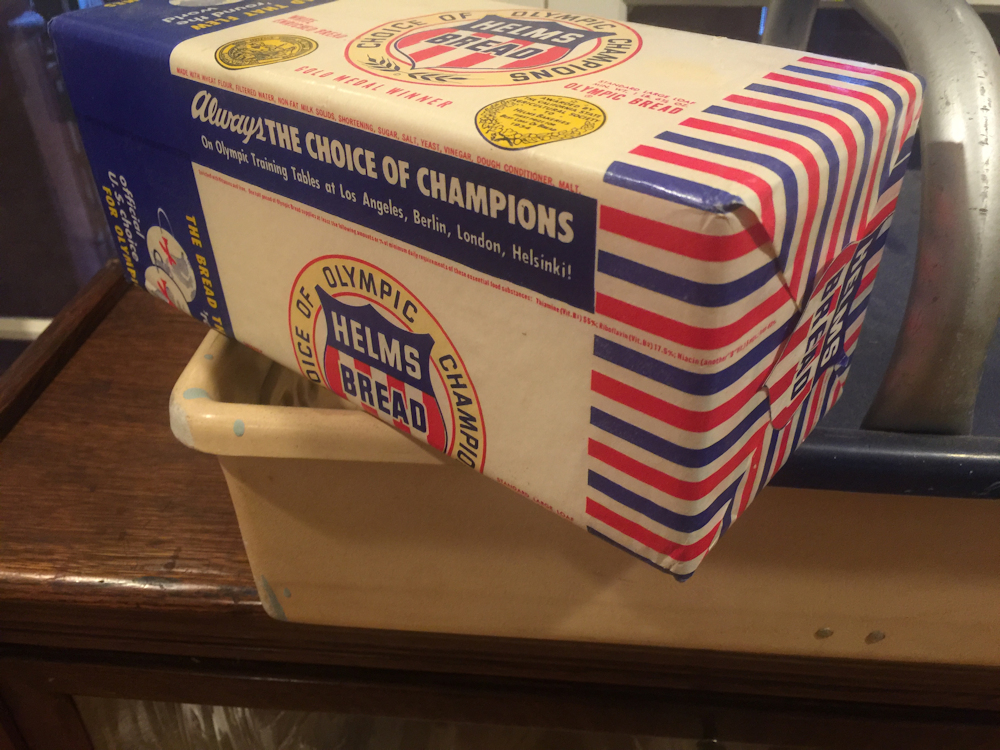

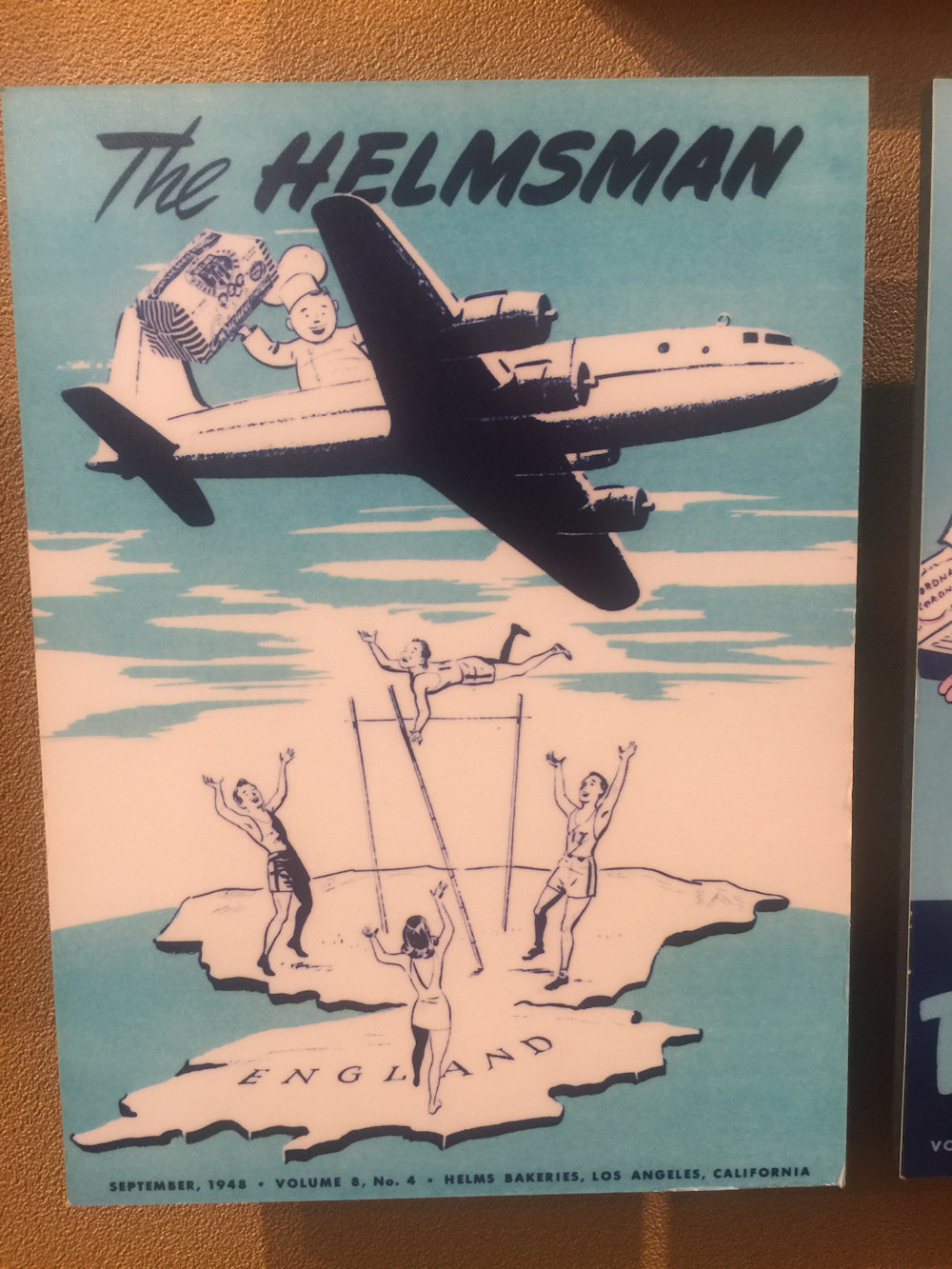

Lee Bixler, proprietor of the Helms Museum refers to Helms as “the P.T. Barnum of bread,” adding, “Helms abhorred the term “truck” and once stated, “Garbage is delivered in trucks. My bread is delivered in coaches.” Helms won the contract to supply bread to the 1932 Summer Olympic athletes, and promptly emblazoned their packaging with the branding “Helms Olympic Bread.”The company peaked when Helms bread blasted off on Apollo 11 for the July 20, 1969, moon landing.

By 1963, Helms 800 trucks drove a total of 75,000 miles a day (this equals the distance of 3 times around the world every day). Helms set their record for stops at 250,000 per week. Plenty of folks remember how the driver, called “the Helmsman,” handed out broken cookies and day-old donuts to neighborhood kids along his route while mothers bought fresh loaves of bread, pastries, cream puffs, pies and other baked delicacies. The trucks were famous as far north as Central California all the way south to the Mexican border. As they slowly traveled down neighborhood streets they would blow their well-recognized Helm’s whistle and children and house wives would run to the trucks. Today the whistles are very rare and almost impossible to locate. Drivers stacked crates of bread loaves up front and used the drawers mostly for pastries. Helms wanted people to get in the truck, yank out the drawers and look at the stuff, and say, here’s what I want. It was not just a delivery. It was a selling tool for Helms.

The first model of this truck was produced in 1929 and was known as the Divco-Twin (the company was known for making a twin engine bus). The Twin Coach name was dropped in 1944. Henceforth, the company was known simply as the DIVCO Corporation. DIVCO became known for its unique patented “Stand and Drive” mechanism. The delivery man used only two pedals to operate the coach, a unique arrangement whereby the left pedal functions first as a clutch; then, when pressed further, it engages the hydraulic brakes. ” Company promotional material noted this was for “safety” and special care needed be taken when learning to drive in the semi-standing position. The DIVCO components were designed and built to run 300–500 thousand miles.

World War II changed everything. Heavy industry focused on the war effort, and production of anything nonessential ceased. One of the rarest DIVCO trucks is the two-year production 1947 – 1948 built only for the Helms Bakery. During WWII aluminum was at a premium and because every DIVCO Coach was “skinned in aluminum”, production was halted abruptly in 1941. In 1947 Paul Helms contacted DIVCO in order to refresh his fleet. He was told DIVCO was never resuming production of its Coach model postwar. He told DIVCO his drivers were running home delivery routes and needed the short wheelbase and tight turning radius of the Coach to turn from one curb to another and couldn’t drive their routes in the larger “Snubed Nosed” milk trucks. DIVCO still retained many spare parts and all of the tooling for the Coaches. DIVCO told Helms they would “tool up” for one last production-run of Coaches. Helms was told to order all he needed because after 1948 there would be no more Coaches built. Every Coach built in 1947 – 1948 was sold to the Helms Bakery. They were the only ones with the larger rear “cargo-plane” doors which hinge at the sides of the vehicle opening 90 degrees allowing for full-width loading.

Interesting footnote: When home delivery began horses drawing the wagons learned the delivery route. While the driver was walking to the front door of a customer’s home the horse would walk the wagon to the next customers home. DIVCO trucks have a very low first gear so it was possible for the driver to set the truck in low gear to creep by itself to the next house with the right wheels running in the gutter. This was called “Walking the Truck.”